Avoid the Public Mold Trap: The Definitive Guide to Identifying Industrial-Grade Remote Controls

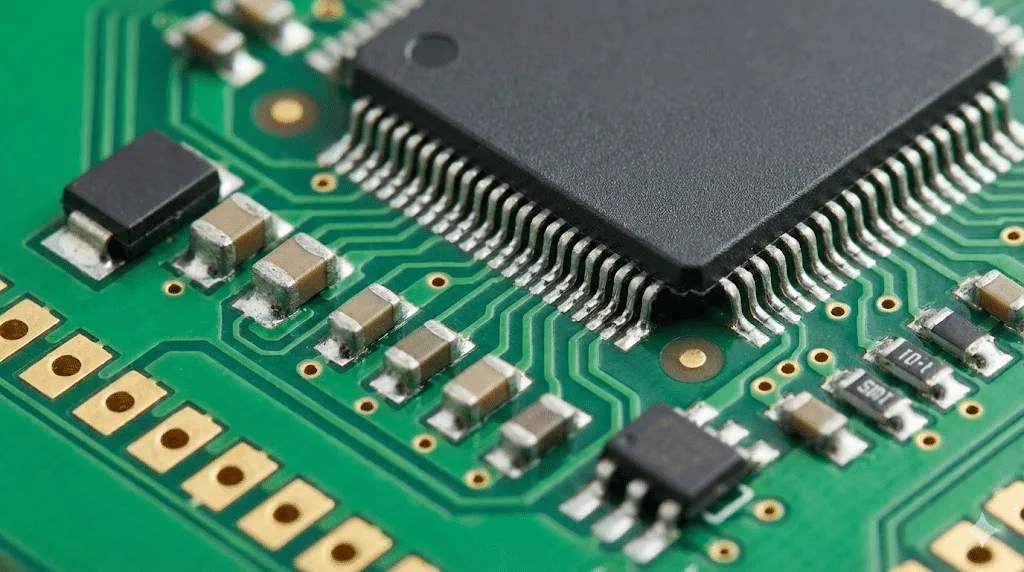

Why do identical-looking remotes perform differently? We dismantle the PCB to reveal the hidden differences in FR-4 material, soldering, and RF stability that impact your reputation.

Key Takeaways

- Public mold remotes cut costs at PCB, oscillator, and QA, causing drift, desync, and early failures.

- Industrial-grade requires FR-4, crystal or SAW references, proper RF layout, and 100% AOI.

- Field tests: squeeze, drop, and inspect board color or oscillator to spot paper boards and LC designs.

In the global electronics market, a dangerous paradox exists for every professional locksmith and distributor: the "Public Mold" paradox. You can find ten remote controls that look identical on the outside, yet their wholesale prices range from $1.50 to $5.00.

For a distributor, the cheaper option is tempting. It promises higher margins. But as a source factory with 10 years of RF manufacturing experience, GateRemoteSource knows the uncomfortable truth: the casing is only a mask. When a customer calls three months later saying their gate will not open in the rain, or the remote has lost programming, the shell is not to blame. The failure sits inside the PCBA (Printed Circuit Board Assembly).

This guide dismantles the technical differences between market junk and industrial-grade hardware. It gives you clear, verifiable data points to check before you place an order.

1) The Substrate: Why Paper Belongs in Books, Not Remotes

The cheap option: Phenolic paper board (94HB/94V0). Low-end manufacturers use "yellow board" composed of paper impregnated with phenolic resin.

The physics of failure: Paper is hygroscopic. In humid environments, the board swells microscopically. That swelling stresses copper traces and solder joints, leading to intermittent micro-fractures.

Engineer's Tip: The Van Test If an installer leaves these remotes in a service van at 60 C or above, thermal expansion mismatch warps the circuit. Failure rate in this scenario exceeds 15%.

The GateRemoteSource standard: FR-4 glass fiber. We use FR-4 epoxy glass fiber boards (woven fiberglass plus epoxy). It holds structural integrity from -40 C to 100 C.

Need FR-4 and AOI-verified remotes?

Get a teardown sample kit showing FR-4 boards, crystal references, and AOI reports before you commit volume.

2) RF Stability: The Heartbeat of the Remote

Ever encountered a remote that works from 50 meters one day but fails at 10 meters the next? This "ghost range" issue is usually caused by the frequency reference component.

The cost-down method: LC or RC oscillation. To save about $0.15 per unit, cheap workshops remove the crystal oscillator and rely on LC or RC circuits. These are highly sensitive to temperature drift. A standard 433.92MHz remote using LC oscillation can drift to 433.50MHz on a cold morning.

The industrial method: Quartz crystal or SAW resonator. We use industrial-grade quartz crystal oscillators or SAW resonators, with a strict frequency tolerance of +/- 10 ppm to +/- 75 kHz. Even if battery voltage drops or temperature swings, transmission stays locked.

3) The Hand Effect and Antenna Design

The human body is a large bag of conductive salt water. When a user grips a poorly designed remote, their hand detunes the antenna.

Cheap layouts: Generic copy-paste antenna traces often run too close to the battery or ground plane. When held tightly, transmission power can drop by 30-50%.

GateRemoteSource engineering: We design a dedicated antenna clearance zone, match impedance to 50 ohms, and use large ground planes to shield the oscillator. Transmission stays consistent whether pinched or full-grip.

4) The Chipset: Rolling Code Integrity

For locksmiths, the nightmare is not just hardware failure. It is data loss. Many cheap remotes claim rolling-code compatibility (for example HCS301) but use unstable imitation chips.

The problem: Clone chips often have weak sync logic. After enough presses out of range, the remote and receiver lose sync.

Our approach: We prioritize genuine protocol compatibility and robust sync algorithms. Our firmware keeps the hopping-code window wide enough to prevent de-synchronization during normal use.

5) Manufacturing: The Invisible 10%

Design is half the battle. Manufacturing consistency is the other half.

- AOI (Automated Optical Inspection): Every board passes AOI. High-res cameras reject tombstoned resistors or dry joints instantly. Defect rate stays under 0.1%.

- Conformal coating (three-proof paint): For high-end export orders, we apply a transparent insulating layer over the PCB. It protects against humidity, salt spray, and sweat if the casing cracks.

6) Technical Comparison: Cheap vs. Industrial Grade

| Feature | Cheap Public Mold | GateRemoteSource Industrial |

|---|---|---|

| PCB Material | Phenolic Paper | FR-4 Glass Fiber |

| Temp Range | -10 C to 50 C | -40 C to 100 C |

| Frequency Source | LC or RC (drift) | Crystal or SAW (+/- 75 kHz) |

| Button Life | ~15,000 (iron) | >100,000 (steel plus silver) |

| Inspection | Manual sampling | 100% AOI |

| Defect Rate | ~3% | <0.1% |

| Coating | None | Conformal (optional) |

7) How to Field-Test a Remote (For Locksmiths)

- The Squeeze Test: Squeeze the case near the buttons. If it activates without a press, the PCB is flexing (likely paper board).

- The Drop Test: Drop from 1.5 meters onto a hard floor three times. If the battery clip flies off or frequency shifts, soldering is weak.

- The Board Inspection: Open it up. Green or blue board? Likely FR-4 (good). Yellow or brown board? Likely paper (bad). Silver metal can? Crystal oscillator (good). No metal can? LC or RC oscillation (drift risk).

Conclusion

Manufacturing is not just assembly. It is about delivering certainty. A remote control is the only interface between your customer and their security system. If it feels cheap or fails, they will not blame the factory in China. They will blame you. We leverage 10 years of manufacturing heritage to ensure what is inside the shell is built to last.

Ready to upgrade your supply chain?

Get a teardown sample kit and wholesale pricing tailored to your SKUs.

FAQ for Technicians

Q: Why does frequency drift happen in cold weather? A: Cheap remotes use LC or RC circuits without temperature compensation. We use crystal oscillators that remain stable in freezing conditions.

Q: Can I tell if a remote is high quality without opening it? A: Not always, but the Squeeze Test is a good indicator. If the casing flexes and triggers the button, the internal PCB is likely a low-quality paper board.

Q: What is rolling code de-synchronization? A: It occurs when the remote's counter gets too far ahead of the receiver. Our industrial chips use a wider window to prevent this common lockout issue.

Need a custom PCB layout or private-label remote? Contact our engineering team to discuss your requirements.

Related Articles

Programming

Garage Remote Pairing Checklist for Field Installers

A practical on-site SOP to pair remotes faster and reduce callback risk across mixed-brand gate projects.

Installation Guides

Nice, Came, Hormann Compatibility Guide for Wholesale Buyers

A procurement-first matrix to match OEM families, frequency bands, and replacement SKUs before bulk ordering.

RF Engineering

How to Choose a 433.92MHz RF Remote Control for Garage Doors and Roller Shutters: Distance, RF Anti-interference, and Compliance

A field-proven checklist for OEM teams to turn range and compliance into measurable KPIs: link margin, blocking, protocol airtime, and regulator-limited transmit behavior.